Solution for Rail Transit Vehicle Communication Service Platform

At present, China's rail transit construction has entered a stage of rapid development, with strong demand for the construction of major rail projects. Railway electrification renovation, new line construction, passenger dedicated line construction, urban light rail, subway, etc. are also in full swing.

Today's high-speed railway has become one of the important means of transportation for us to travel long distances. The high-speed railway from sunrise to sunset makes a thousand miles away become within reach, and the domestic high-speed railway is over 20000 kilometers long.

However, train ground communication has always been one of the technical difficulties when trains are running at high speeds. Regarding the above situation; Jizhida has launched the Rail Transit Vehicle Communication Service Platform Unit (ESU) based on the characteristics of the rail industry. The solution of broadband wireless communication technology.

Introduction to ESU Equipment

The train ground communication of high-speed railway trains has always been one of the technical difficulties. The broadband wireless communication technology solution has solved many technical difficulties and made the operation of the railway industry possible.

The onboard communication service platform unit (ESU) for rail transit is a communication service equipment located in the train carriage based on broadband wireless communication (EUHT). ESU is the basic Ethernet communication and operation system of the vehicle, providing train network for onboard WiFi wireless network system, video monitoring system, passenger information and entertainment system, and other services. It also has storage and operation functions. ESU is independent of various access systems and is part of the vehicle equipment.

There are currently three standards under research and development for high-speed railway train ground communication: LTE-G, satellite, and broadband wireless communication technology (EUHT). ESU is a network and service equipment based on this technology, which has a large bandwidth, stable continuity, low cost, easy implementation, and can greatly improve the bandwidth of train ground communication and enhance service projects and levels.

This product is mainly used in the carriages of high-speed rail passenger trains, and can also be used in the carriages of subway bullet trains. Each carriage is equipped with one unit, and it can also involve the design, installation, operation and maintenance software, safety protection software, equipment entrance management and other software.

Through the implementation of this product, real-time video transmission from the car to the station can be solved, providing technological technology for public transportation safety. At the same time, WIFI access function can also be provided, solving the wireless internet problem that passengers are generally concerned about.

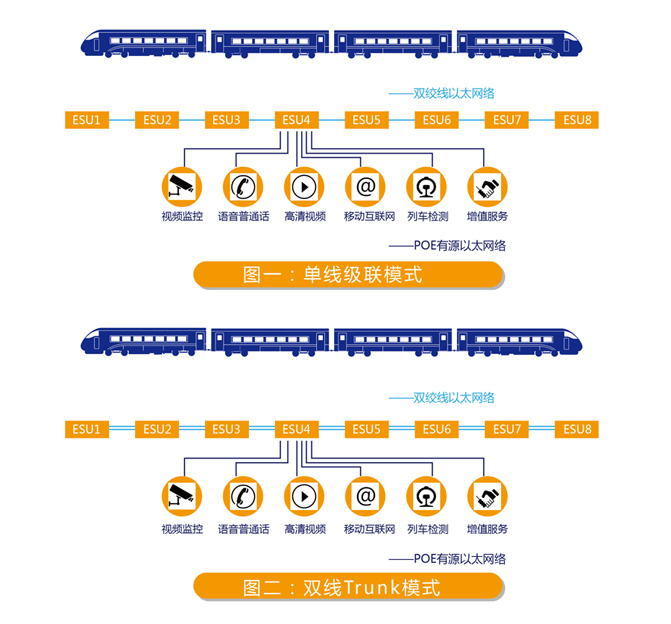

As shown in Figures 1-2, the device consists of two layers of networks. Firstly, a cascaded cross connection ring network is used, which is a cable network composed of broadband wireless communication equipment units (EAUs) and ESU devices. EAUs can be one or two. ② Adopting a port to port networking approach, a PoE network consisting of ESU and business units. Both layers of the network use IEEE 802.3 (Ethernet) protocol. The on-board communication service platform unit of rail transit is not only an industrial control computer, but also integrates the function of a switch

2: ESU main functions

ESU devices cover switch and industrial computer functions, with the main functions and indicators as follows:

1. The ESU device has the following functions:

ESU equipment is based on IEEE 802.3 (Ethernet) protocol, providing data transmission network and information services for train carriages, mainly completing the following functions:

① Differentiate service types based on the ports where broadband wireless communication transceivers (EAUs) receive data, and achieve differentiated transmission of QoS data according to different service types;

② Based on the QoS of different ports of EAU, achieve balanced output of traffic to multiple wireless outlets for specific QoS data;

③ Implement multi replication output of specific QoS data to multiple wireless outlets based on different port QoS of EAU;

④ Implement routing forwarding function from ESU access port to different wireless exit ports;

⑤ Implement special customized application computing services on ESU.

2. ESU device network communication function

2.1 Loop Network Interface Function

① The Ethernet network bandwidth shall not be less than 1Gbps/s.

② The Ethernet interface has a cascading interface.

③ Ethernet networks have ring network functionality.

④ Ethernet interfaces should use reliable and shockproof interfaces that meet the requirements of the usage environment.

2.2 PoE Active Ethernet Interface Function

① PoE active Ethernet network has a bandwidth of no less than 1000Mbps per port.

② The number of PoE ports is 8.

③ The PoE port outputs a power supply voltage of 47V-55V and a power supply current of 350mA.

④ PoE port power supply should have short-circuit protection measures, and any short circuit on one side should not affect the power supply of other ports.

⑤ The PoE port adopts an end-to-end connection method with the business unit.

⑥ PoE ports should use reliable and shock resistant interfaces that meet the requirements of the usage environment.

2.3 Network Interface Function

① The ESU device has 4 cascaded interfaces and a network bandwidth of not less than 2Gbps/s.

② ESU devices have 8 PoE interfaces, each with 10M/100M/1000M adaptive capabilities.

③ MDI/MDIX adaptive.

④ Can store 4096 MAC addresses.

⑤ The device has a fast routing function for multiple to multiple ports, with a port routing forwarding capability of not less than 1Gbps per port, MTU (Transmission Unit Length) less than or equal to 2K, and latency less than 50us.

⑥ Equipped with application business cache function, capable of caching data transmitted by different users within 1 hour.

⑦ Equipped with user access authentication function that can be negotiated and agreed upon with the ground.

⑧ Capable of managing access devices.

⑨ The device processor should be able to identify customized services and data transmission services based on message types, and forward and process data according to service QoS types.

⑩ The device processor should be able to select the appropriate wireless transmission channel based on the real-time wireless transmission status of the front EAU and rear EAU, according to the data message level, and achieve dynamic flow balancing.

⑪ The device processor should be able to select the appropriate wireless transmission channel based on the real-time wireless transmission status of the front EAU and rear EAU, according to the data message level, and achieve data replication and transmission according to the configuration requirements.

2.4 Equipment Power Supply

① The ESU equipment is powered by 110V DC, with a power fluctuation range of 77V to 138V, or AC220V.

② The power supply interface should adopt a reliable and earthquake resistant interface.

2.5 Equipment RAM indicators

① The service life of ESU equipment is 8 years.

2.6 Equipment usage environment indicators

① The working environment temperature ranges from -25 ℃ to+70 ℃.

② The relative humidity should not exceed 90% (at a temperature of 30 ℃).

③ The atmospheric pressure ranges from 70kPa to 106kPa (equivalent to an altitude below 3000 meters).

④ The impact vibration shall be carried out in accordance with Grade A of GB/T 25119-2010.

⑤ The protection level shall be implemented according to IP32.

⑥ The cooling method is executed without the need for active cooling.

2.7 Equipment Electromagnetic Compatibility Index

① Electrostatic discharge: shell contact discharge 6KV, air discharge 8KV, Class B.

② Radio frequency electromagnetic field radiation: 80MHZ-1GHZ, 10V/m, Class A

③ Electric fast pulse group: power cord, 2KV 5/50ns, 5KHZ repetition frequency, Class B;

④ Surge: Power line, 1KV between lines, 2KV between lines and ground, Class B;

⑤ Conducted harassment: power line, signal line, 10V, 150KHZ-80MHZ, Class A;

⑥ Conductive emission: power cord, Class A;

⑦ Radiation emission: casing, Class A.

⑧ The equipment ground should be insulated from the vehicle's electrical ground, and the protective discharge circuit should discharge the impact energy to the vehicle's ground circuit instead of the equipment's ground circuit.

2.8 Equipment Structure

① The equipment adopts a chassis box installation structure.

② PoE interface, power interface, interface adopts a front plug structure.

③ The front end of the device should display indicator lights, including system lights, alarm lights, and port indicator lights (indicating whether the port is working).

④ The device should have a reliable configuration interface for connection.

⑤ The casing should have a reliable grounding point.

⑥ The equipment size is 440mm * 330mm (not exceeding this size) * 44mm.

⑦ The equipment should have reliable and installed threaded holes.

ESU system external interface

The switch section provides: 1 Console debugging port, 1 Gigabit RJ45 interface for easy device maintenance and use, 12 M12 Gigabit Ethernet interfaces, of which two sets of ports support Bypass function. When not in Trunk networking, one set of two ports can be used as normal ports, and the remaining 8 ports support POE function, which is implemented through two expansion slots.

ESU built-in industrial control motherboard specifications

CPU and Memory

CPU: 5th generation Intel ® Brodwell ™ Core ® I3/I5/I7 U series low-power dual core CPU, choose CPU according to application requirements;

CPU model

i7-5650U

i5-5350U

i3-5010U

system bus

5 GT/s

5 GT/s

5 GT/s

Cache

4 MB Smart Cache

3 MB Smart Cache

3 MB Smart Cache

CPU instruction set

64-bit, SSE 4.1/4.2, AVX 2.0

64-bit, SSE 4.1/4.2, AVX 2.0

64-bit, SSE 4.1/4.2, AVX 2.0

CPU process

14 nm

14 nm

14 nm

CPU core

2 cores and 4 threads

2 cores and 4 threads

2 cores and 4 threads

Basic working frequency

2.2 GHz

1.8 GHz

2.1 GHz

Rui Pin

3.1 GHz

2.9 GHz

Typical power consumption

15 W

15 W

15 W

Integrated display model

Intel ® Iris ™ Graphics 6000

System chipset: Board mounted Intel ® Brodwell ™ SOC CPU/chipset, integrated graphics card, CPU SMT board mount, suitable for earthquake resistant application environment of trains;

BIOS: 16 Mbit Flash BIOS

RTC Battery: Rechargeable Lithium 3.3V/55mAh CR2302 Battery with -40 ° C-80 ° C Wide Temperature Operation

System Memory: Board mounted 8GB DDR3-1600 low-voltage memory, suitable for earthquake resistant application environments on trains;

display

Chipset: Intel ® HD6000 series graphics

HDMI/DVI-D display interface, supports connecting displays for debugging during production assembly and maintenance, and also supports network to HDMI/DVI interface for connecting to PIS systems

Ethernet

Chipset: 3 Intel chips ® I210 Gigabit Network, supporting 4000V lightning surge protection

Speed: 10/100/1000 Mbps, supports network wake-up and Link/Speed LED lights

Standard: Compliant with IEEE 802.3 IEEE 802.3u、IEEE 802.3x、IEEE 8023y、IEEE 802.ab

LAN1/LAN2 and RS232 signals are integrated into the adjustment connector for communication and data exchange with the switch motherboard; LAN3 is an RJ45 interface used for debugging and maintenance purposes;

Expand I/O interface

Watchdog Timer: A 255 level interval timer, set in software according to the provided watchdog routine. To support restarting the motherboard in case of hardware or software crashes;

Serial port:

-1 x RS232, supports 4000V surge protection, 3, automatic flow direction, flow control. Synthesize with network signals in connectors and communicate with switches;

USB:

-2 x USB 3.0 compliant interfaces

Automatic: High definition automatic encoding

-Realtek ALC6622 sound card with MIC/sound output

Expansion interface: Supports 1 full-length Mini PCIe slot to expand other functional interface cards (such as WIFI modules)

Storage:

-Onboard 32GB SSD electronic drive for installing embedded operating system (embedded LINUX)

-1 SATA and power interface, used for connecting mechanical hard drives or SSD electronic drives, storing data for use

Power supply and power consumption

Input voltage: DC 12V@5A Input,

Power on type: AT/ATX jumper selection

Power management: ACPI 3.0, APM

The previous text introduced the onboard communication service platform for rail transit. Nowadays, the information technology of railway engineering carries the data model of railway structures, and the Jizhida rail transit on-board communication service platform unit is integrated into it to assist the development of rail transit technology.