Industrial level teaching application of six axis robotic arm

Product Introduction

Ethernet communication

·Based on Ethernet communication, micro robots provide a scalable distributed control system,

It is also a tool for Ethernet related training.

Industrial Robot Design

·Referring to the design of general industrial 6-axis articulated robots, the construction method of micro robots is the same. Its bare metal mechanical structure is easy to learn about the structure of industrial robots

Open development environment

·The micro robot comes with a practical tool that allows for direct operation of the robot. The Windows platform also provides a robot control API, allowing users to develop any type of robot application using its openness

main features

-Based on Ethernet

-Compact design

-Suitable for the education industry

-Standard 6-axis articulated robot

-Control cabinet

-Robot Control API

-Joint type 6-axis robot

-Open Robot Controller

Product specifications

robot

freedom: six

Payload: 1kg

Drive system: Ethernet closed-loop stepper

Position feedback: incremental encoder

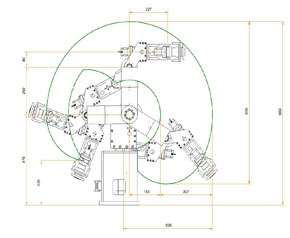

Scope of operation: 590mm (maximum)

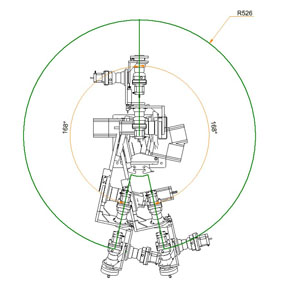

- J1: ±175°

- J2: + 110°~ -92°

- J3: + 63°~ -153°

- J4: ±175°

- J5: ±92°

- J6: ±180°

Reproducibility: ±0.12mm

Weight: arm 30kg

Input voltage: single-phase 100~240Vac

controller

DI/O: 15 ch DI/16-ch DO (DB37 connector)

1 x Intel ® GbE LAN port 1 x VGA

2 x USB 2.0 (external)

1 x USB 3.0, 1 x USB 2.0 (inside the control cabinet)

1 x Emergency braking end

Weight: Control cabinet 20kg

software

NexGRC runtime (robot controlled runtime)

NexMotion studio (configuration program) standard robot motion control function

Supports C \ C++, C # and VB. Net User Programming

OS: WES7

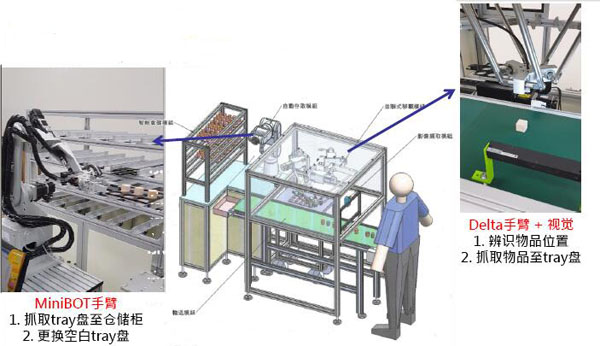

- 智慧产线示范线